-

Products

- Lab Instruments

- Lab Meters and Probes

- Chemistries, Reagents, and Standards

-

Online Analyzers

Ammonium Analyzers Ammonia Monochloramine Analyzers Chlorine Analyzers

- CL17sc

- CL10sc Amperometric

- 9184 sc Amperometric

- Ultra Low Range CL17sc Colorimetric Chlorine Analyser

EZ Series Analysers- Iron

- Aluminium

- Manganese

- Phosphate

- Chloride

- Cyanide

- Fluoride

- Sulphate

- Sulphide

- Arsenic

- Chromium

- Copper

- Nickel

- Zinc

- Ammonium

- Total Nitrogen

- Total Phosphorus

- Phenol

- Volatile Fatty Acids

- Alkalinity

- ATP

- Hardness

- Toxicity

- Sample Preconditioning

- Boron

- Colour

- Nitrate

- Nitrite

- Silica

- Hydrogen Peroxide

- Sodium

- EZ Series Reagents

-

Online Sensors and Controllers

Digital Controllers (Transmitters) Controllers (Analog)

- SC4500

- Orbisphere 410/510 Carbon Dioxide

- Orbisphere 410/510 Oxygen

- Orbisphere 410/510 Ozone

- Orbisphere 51x Hydrogen

- Orbisphere 51x Nitrogen

- Pro Series

pH & ORP Sensors- 1200-S pH

- 12mm pH/ORP

- 8362 sc High Purity

- Combination pH/ORP

- Differential pH

- Digital Differential ORP

- Digital Differential pH

- LCP ORP

- LCP pH

- Samplers

- Test Kits & Strips

- Microbiology

-

Lab Equipment and Supply

Apparatus

- Brushes

- Clamps, Rings & Stands

- Crucibles

- Crucibles & Casseroles

- Dispensers & Droppers

- Grab Samplers

- Oil and Grease

- Other Apparatus

- Pipet Aids

- Pipettes

- Racks

- Stir Bars

- Tubing

- Weighing Accessories

Instruments- Anemometers

- Balances

- Floc Testers/Jar Testers

- Hot Plates & Stirrers

- Moisture Analysers

- Other Instruments

- Ovens & Incubators

- Refractometers

- Thermometers

- Timers

- Vacuum Pump

- Water Purification Systems

- Automated Lab Systems

- Parameters

-

Software Solutions

-

Claros Water Intelligence System

Product Pillars Process Management

- Solutions For:

- BOD/COD Removal

- Nitrification/Denitrification

- Phosphorous Removal

- Sludge Management

Data Management- Solutions For:

- Collection

- Visualization & Analytics

- Reporting

- Data Accuracy

Instrument Management- Solutions For:

- Maintenance

- Troubleshooting

- Remote Access

- Lab and Process Comparison

Industry Challenges Regulatory Compliance Cost Savings Remote Operations Process Optimisation Equipment MaintenanceClaros News Claros Software Release Notes

-

Claros Water Intelligence System

- Industries

- Brands

- Support

- News & Events

Hach South Africa

Choose your country or region:

Europe

Americas

Asia - Australasia

- Australia

- Mainland China

- India

- Indonesia

- Japan

- Malaysia

- New Zealand

- Philippines

- Singapore

- South Korea

- Thailand (Thai)

- Taiwan

Middle East - Africa

Municipal Wastewater

Wastewater Treatment Processes – Doing More With Less

Each wastewater treatment plant is unique, with its own capacity, layout, processes and equipment, and effluent limits. And each plant is faced with rising energy and chemical costs, and regulations that change or become more stringent over time.

At Hach ®, we embrace the challenge to continuously improve wastewater monitoring equipment and processes, including nutrient removal, aeration control, nitrification/denitrification, sludge dewatering, and other plant operations. Whether in primary, secondary, or tertiary treatment of wastewater, or in understanding solids handling, regulations , Hach innovations and new applications can help you stay in compliance and reduce operating costs, doing more with less - with the confidence that your plant is running smoothly.

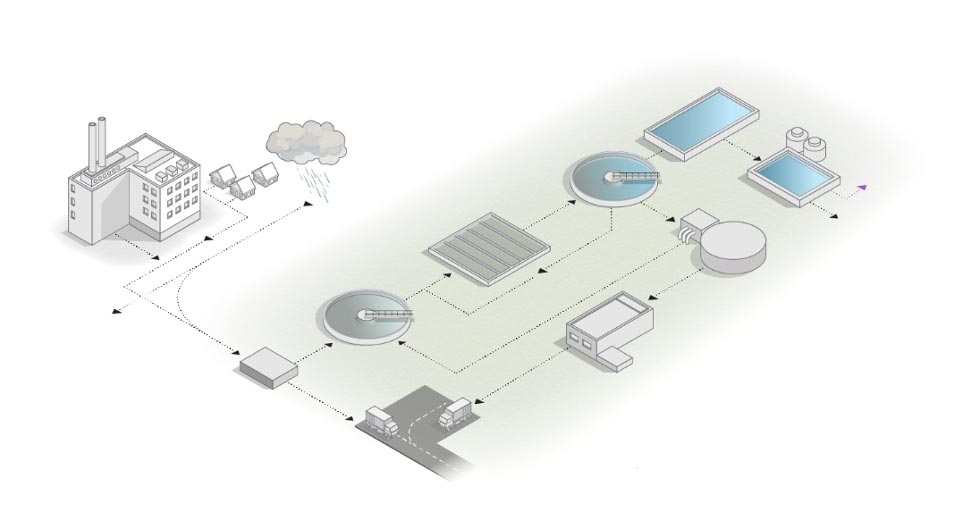

Wastewater Treatment Overview

Collection Systems

Modern sanitary sewer collections systems move wastewater through a series of pipes from residential buildings, businesses, and industrial sites to wastewater treatment facilities for processing and discharge. Some older systems know as combined sewer systems also carry stormwater runoff in addition to the wastewater from residential and commercial sources.

The wastewater flows through underground sewer mains, most often by gravity, but sometimes assisted by pumps situated at lift stations. Depending on the topography of an area, these force mains vary in length up to a few miles long. Interceptors are locations where two lines meet and flow into a larger pipe, and can include large chambers accessible by manholes.

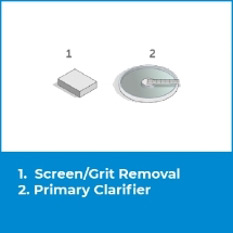

Preliminary and Primary Treatment

Preliminary treatment is typically the first process within the treatment plant, and consists of screening and de-gritting. Screening is the process of removing trash, rags, and other debris by passing the water through a mechanical screen or rotating drum. Grit is removed by reducing the velocity of the wastewater so that heavier inorganic particles like pebbles and sand can settle to the bottom and be removed via gravity. The grit and screenings are washed and compacted before being collected in a dumpster. These preliminary processes are very important for modern water resource recovery facilities, as grit and debris can irreparably harm downstream processes including primary clarifier mechanisms, aeration diffusers, and membranes.

During primary treatment, primary clarifiers allow organic solids to settle through gravity, while fats, oils and greases are allowed to float to the surface. The settled solids are referred to as primary sludge, and often are thickened in a downstream process before delivery into an anaerobic digester. The floating fat, oil and grease is collected from the surface and are typically added directly to the anaerobic digester. A typical primary clarifier will remove approximately 70% of the solids and 45% of the Biochemical Oxygen Demand from the screened wastewater. Modern facilities that operate enhanced biological nutrient removal processes often extract or ferment the carbon in the primary sludge and dose this side stream into anaerobic or anoxic processes downstream, as a food source for the respective biology.

Secondary treatment

Secondary treatment removes the soluble organic matter, nutrients such as nitrogen and phosphorus, and most of the suspended solids that escape primary treatment. Most often, biological processes are used in which microbes metabolize organic compounds and nutrients to grow and reproduce. The two most common biological secondary treatment processes are attached growth and suspended growth systems. A suspended growth process fosters the growth of suspended microorganism flocs from individual organisms already present in the wastewater and in the return activated sludge. The flocs contain organisms that can remove the pollutants through aerobic, anoxic, and anaerobic environments. Once the pollutants are removed, the flocs are sent to a secondary clarification process where they separate from the water via gravity. A portion of sludge in the bottom of the secondary clarifier is then directed back upstream to blend with the primary effluent (Return Activated Sludge) to create mixed liquor. The remainder of the sludge is removed from the process (Waste Activated Sludge) to create the ideal ecology of microorganisms. Attached growth systems rely on the microorganisms to attach to a media, and create a biofilm. The settled sewage is either mixed or sprinkled over the biofilm coated media where the microorganisms remove the pollutants. Like the suspended growth process, biofilm fragments and suspended flocs are sent to a secondary clarifier for separation where sludge is recycled and wasted and clean water is discharged to the next process.

For biological treatment to function efficiently, organisms require nutrients in a balanced ratio, including carbon, nitrogen, and phosphorus (referenced as C:N:P), as well as trace elements including iron, copper, zinc, nickel, manganese, potassium, sulfur, and other components which are typically present in wastewater. The commonly accepted C:N:P Ratio is 100:5:1, although some facilities thrive outside of this ratio, while others experience polysaccharide slime formation or filamentous bacteria growth that inhibit the biology and settling in the secondary clarifier.

Multiple biological processes can be employed to complete secondary treatment, including plug flow aeration basins, complete mix aeration tanks, sequencing batch reactors, oxidation ditches, trickling filters, moving bed biological reactors, integrated fixed film activated sludge, and others.

Biological Nutrient Removal (BNR) alters the environment of the microorganisms to remove nitrogen and phosphorus from the water. A BNR process consists of anaerobic (no oxygen or nitrate), anoxic (no oxygen, nitrate is present), and aerobic (oxygen present) stages, during which the water is moved through a series of chambers to perform various biological functions.

Chemical treatment processes can also be used, such as the chemical removal of phosphorus. By introducing a chemical precipitant to within the aeration basin and clarifiers, phosphorus is removed by flocculation, binding into insoluble compounds that settle out and can be removed as sludge.

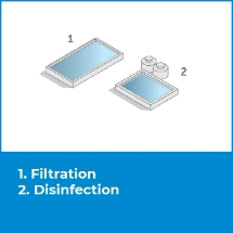

Tertiary Treatment

In tertiary treatment, techniques such as filtration, disinfection, carbon absorption, and other processes are used to remove the remaining organic load, suspended or dissolved solids, pathogens and heavy metals that pass through other treatment processes. Also called effluent polishing, tertiary treatment raises the effluent quality to the level suitable to its intended use, whether for discharge into lakes, rivers, or oceans, reuse as non-crop irrigation (parks, golf courses, greenways, etc), groundwater recharge, or in certain cases, as influent to drinking water plants. Wastewater plant effluent must be monitored to ensure compliance with effluent permit limits, which vary based on jurisdiction and country.

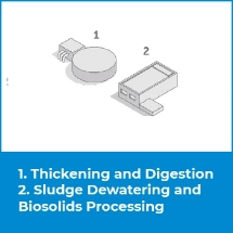

Solids Handling

The method for handling the sludge removed from the process depends on the volume of solids as well as other site-specific conditions. Aerobic digestion is often used by facilities less than eight million gallons per day of inflow. Waste Activated Sludge and if present, Primary Sludge, are added to an aerated reactor where microorganisms feast on the organics and microorganisms present in the sludge to reduce the volatile solids content and the overall mass of sludge. Anaerobic digestion is typically used at facilities greater than eight million gallons per day of inflow, and involves the use of sealed reactors to create an anaerobic environment for different organisms to feast on the organics and microorganisms in the sludge through the processes of acidogenesis and methanogenesis. The methane formed by anaerobic digestion can be used to fuel boilers to heat the digester, flared, or cleaned and repurposed as a green energy source.

Thickening involves concentrating the sludge by removing a percentage of the liquid portion by adding polymer compounds, and is often employed before anaerobic digestion. Dewatering with belt presses, centrifuges or other means further concentrates sludge into a cake. The cake can be further dried, or simply disposed through land application or landfills.

Regulations

Regulations and permit limits vary from region to region and country to country. Generally, target limits are established by the acting authority, and plants measure and report to demonstrate compliance with established limits. In this way, important parameters that indicate water quality and environmental and health standards are monitored and maintained, ensuring the continued health and safety of the populations being served.

For information regarding regulations in the US: https://www.epa.gov/npdes

For information regarding regulations in the EU: https://www.eea.europa.eu/themes/water/water-management

For information regarding regulations in the China: http://english.gov.cn/policies/latest_releases/2015/04/16/content_281475090170164.htm

Effluent & Reuse

While effluent from wastewater treatment facilities is commonly discharged to the environment in rivers, oceans, or other bodies of water, there are a variety of other options for discharge. These include agricultural irrigation; use in parks and recreational facilities (golf courses and sports field irrigation, snow making); wildlife habitat or aquifer/wetland/marsh recharging; industrial uses such as process water; street cleaning; or direct potable reuse where water is sent to a drinking water plant for further treatment.

Service & Support

Online Support

Hach Support Online (HSO) pools more than 70 years of water analysis knowledge into a powerful global community. Flowing directly into our customer and technical support teams, this dynamic resource delivers real-time answers, user-friendly search tools, multiple types of content, and easy ways to connect with Hach experts. With HSO, you get the information you need and together, we can ensure water quality for people around the world.

Technical Training

Hach Training Center provides relevant, hands-on training to your team, giving them the experience they need to master various theories and techniques—and produce results you can trust for quality assurance, environmental safety, and regulatory compliance. Hach experts offer a large course catalog of workshop training, personalized training, and digital learning designed to increase proficiency and confidence for plant operators, instrument and field technicians, laboratory personnel, and plant managers and superintendents.

Service

Hach ServicePlus ® Programs have been developed to help solve your maintenance and support problems. Whether it’s a lack of resources or skills, an instrument that is down, compliance concerns or the need for a predictable budget, we have programs to fit the unique challenges you face in your organization.