Water Quality Analysis for Chemical Manufacturers

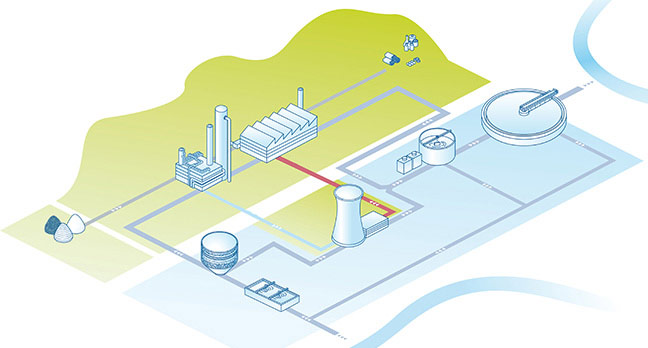

At Hach ®, we understand chemical industry monitoring technology when it comes to maximizing the efficiency and effectiveness of boiler/cooling water and wastewater processes. Since 1947, we have designed, manufactured, and distributed world-class instrumentation, test kits, and reagents for testing water quality in the industrial water cycles of chemical plants.

With Hach as your partner in the chemical manufacturing process, from water sampling and analysis to product loss monitoring and quality control, you can ensure confidence for the tough decisions.

Hach solutions for the chemical industry:

• Online process instrumentation and reagents

• Laboratory equipment, reagents, and supplies

• The most EPA-approved water analysis methods for chemical industry water compliance and chemical

manufacturing regulations

• Portable test kits and field instruments

• Automatic samplers and flow meters

• Prepared media for microbiological testing

• Local sales and service teams

• Service partnership programs

• Customized technical training programs

Process solutions include online sensors that provide round-the-clock support for critical operational and process decision making.

Laboratory solutions include simple, reliable and accurate tests that support quality and compliance decision making.

Process solutions include online sensors that provide round-the-clock support for critical operational and process decision making.

Laboratory solutions include simple, reliable and accurate tests that support quality and compliance decision making.

Process solutions include online sensors that provide round-the-clock support for critical operational and process decision making.

Laboratory solutions include simple, reliable and accurate tests that support quality and compliance decision making.

Calculate Your Savings

How much can your plant save with water analysis solutions from Hach?

Online Support

Hach Support Online (HSO) pools more than 70 years of water analysis knowledge into a powerful global community. Flowing directly into our customer and technical support teams, this dynamic resource delivers real-time answers, user-friendly search tools, multiple types of content, and easy ways to connect with Hach experts. With HSO, you get the information you need and together, we can ensure water quality for people around the world.

Technical Training

Hach Training Center provides relevant, hands-on training to your team, giving them the experience they need to master various theories and techniques—and produce results you can trust for quality assurance, environmental safety, and regulatory compliance. Hach experts offer a large course catalog of workshop training, personalized training, and digital learning designed to increase proficiency and confidence for plant operators, instrument and field technicians, laboratory personnel, and plant managers and superintendents.

Service

Hach ServicePlus ® Programs have been developed to help solve your maintenance and support problems. Whether it’s a lack of resources or skills, an instrument that is down, compliance concerns or the need for a predictable budget, we have programs to fit the unique challenges you face in your organization.